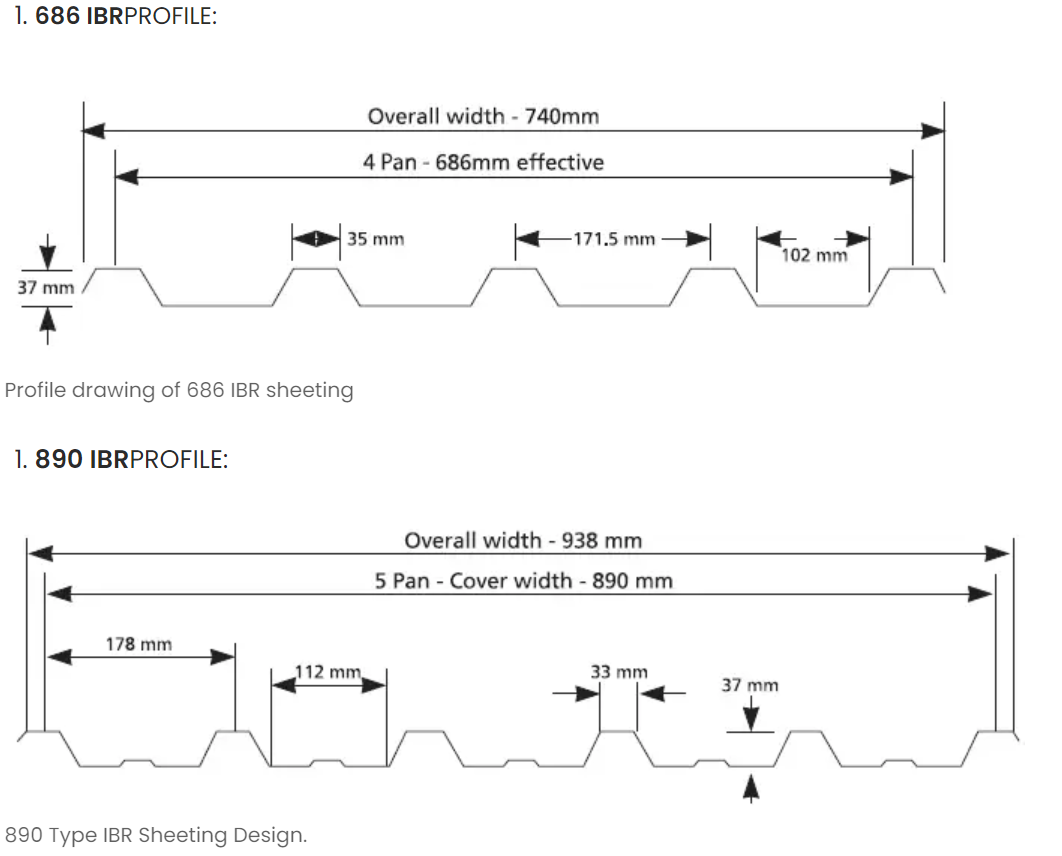

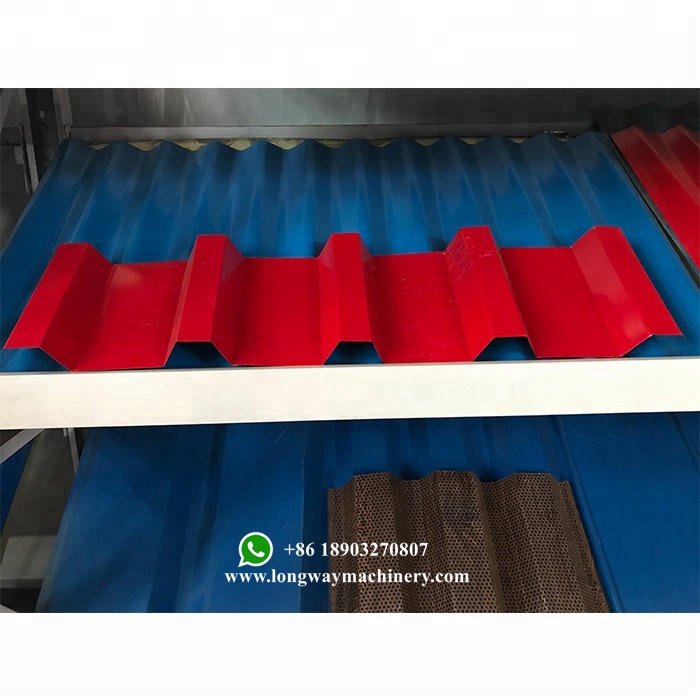

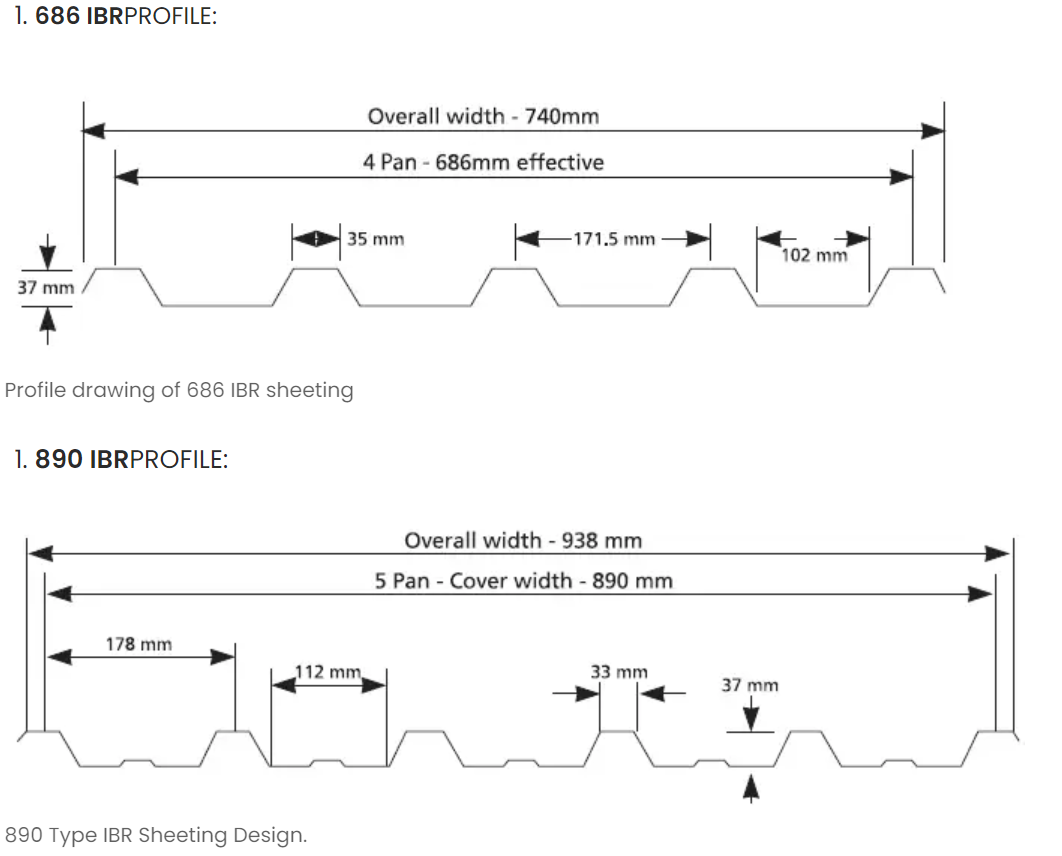

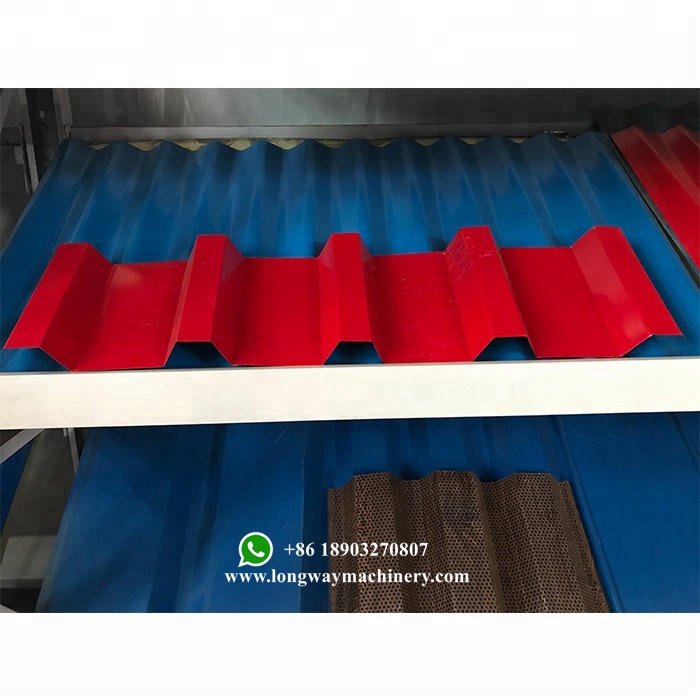

Metal IBR Roof Sheet Roll Forming MachineSince it was first introduced to South Africa in 1958, IBR has enjoyed great popularity for use as side cladding or roofing material in commercial, industrial and residential buildings. IBR got its name from the abbreviation of “Inverted Box Rib”, which has become a household name in the South African building industry. Actually, IBR is a square fluted profile with an effective covering width of 686 mm or 890mm. We have several kinds of design IBR Sheet Roll Forming Machine for IBR sheeting. and all are customized. Our

IBR Sheet Machine is able to form G550 Mpa and thickness up to 0.8mm . And also

Corrugated Sheets Roll Forming Machine is designed for South African Customer.

Machine Components

Similar to other roll forming machines, IBR Sheet Machine consists of decoiler, guiding device, roll former, hydraulic cutter controlled system and product output table. And Auto Stacker is an option.

Details of IBR Roof sheet machine

Details of IBR Roof sheet machine

| Coil Required |

Material |

PPGI GI AL |

| Width |

925mm |

| Thickness |

0.3-0.7mm as custom order |

| Power Required |

Power |

380V 50Hz 3 Phase, 220V, 415V available |

| Main Motor |

5.5KW Siemens Brand |

| Cutting Motor |

4KW Siemens Brand |

| Machine |

Support Frame |

40H Steel |

| Forming Stations |

18 Rows as profile require |

| Structure |

18-20mm |

| Shaft |

75mm Solid shaft |

| Roller |

45# Steel with hear treatment |

| Chain |

1.2inch |

| Bearings |

Standard as custom order |

| Speed |

15-3-m/min |

| Electric Components |

Delta and Siemens brand |

| Size |

7.5*1.3*1.6M |

| Weight |

4T |

Besides of IBR sheet forming machine, We also have corrugated sheet forming machine, Ridge cap forming machine , Floor deck forming machine etc . To request a quote or If you have any questions about our machines, please contact Rebecca anytime .

https://wa.me/message/GFJCYC77KPELM1

Youtube: www.youtube.com/channel/UCFbWECOfV2xeM-WCaww_iPQ