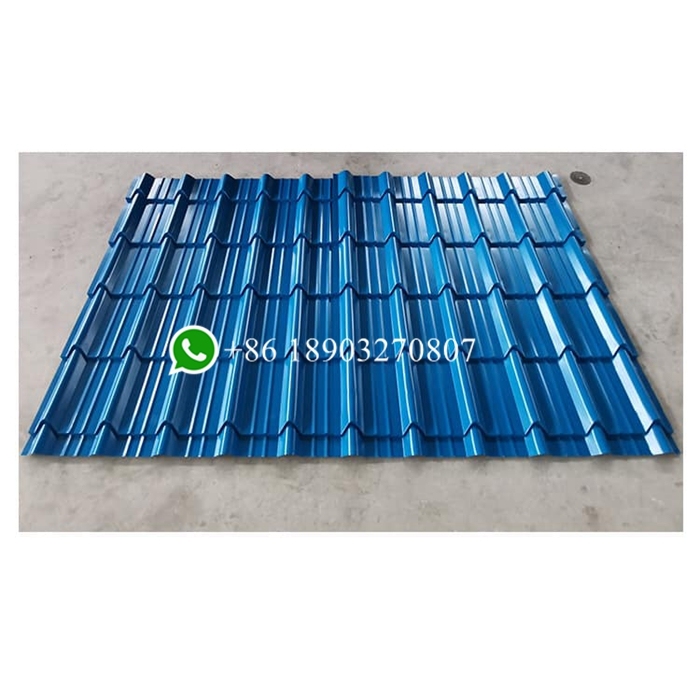

Steel Roofing Step Tile Making Machine Q tile forming machine

Steel Roofing Step Tile Making Machine Q tile forming machine is a very famous tile profile which is widely used in Africa. As usual, the tiles will be covered with a compete polymer costing( Plastic Film). To protect the tile against corrosion, and make the roof durable.

Customer make the tile with a step of 300mm, 350mm and 400mm. With the thickness is from 0.3-0.6mm. The advantage of glazed tile is two special grooves for drainage of condensate from the inner surface of the sheet.

First is the decoiler, which is divided into three categories - manual, electric and hydraulic. Generally speaking, if the customer has no special requirements, we recommend a manual decoiler as a standard configuration. Because the manual decoiler has a low cost, it is more economical and practical. The configuration is sufficient for the trapezoidal tile making machine. But if you require high-speed production and save labor costs, then we recommend that you use a hydraulic decoiler.

Next is the feed Device. We also made a lot of improvements in this part. You can see that we have added two rows of small rubber rollers to prevent scratches on the paint surface, and also added chains or rollers on both sides, equipped with manual broaches to prevent waste Regarding the board and the hand wheel, the feeding width is adjusted. All of these as a whole ensure the flatness of our plates before forming and reduce material waste.

The forming part is generally divided into integral molding and split molding. The difference between the two is mainly in the aesthetics and price difference of the formed sheet. Split molding will increase the number of rows and rolls, so it occupies a larger area and the cost is higher, but the version will be more beautiful. Generally speaking, if our requirements for the version are not too high, overall molding is the first choice.

The next step is the cut-off part. This is generally two ways, electric and hydraulic. Electric is generally used in extreme weather, and hydraulic is more common. Hydraulic cutting has static cutting and servo tracking cutting, depending on the specific requirements. From the structure point of view, there are two forms of single guide post and double guide post. As the name implies, the stability of double guide post is stronger.

The next step is the cut-off part. This is generally two ways, electric and hydraulic. Electric is generally used in extreme weather, and hydraulic is more common. Hydraulic cutting has static cutting and servo tracking cutting, depending on the specific requirements. From the structure point of view, there are two forms of single guide post and double guide post. As the name implies, the stability of double guide post is stronger.

We install the control box on machine . All lines are linked well , customer only need to link power when machine arrive . Program language can be setting in English , spanish etc , as customer need .

The hydraulic station control valve adopts large valves to prevent blockage. And it is equipped with an air-cooled system and is suitable for most areas.

automatic picking and automatic receiving.

Be welded with thicker plate,have long service life.

It has roller table(prevent the material surfing)